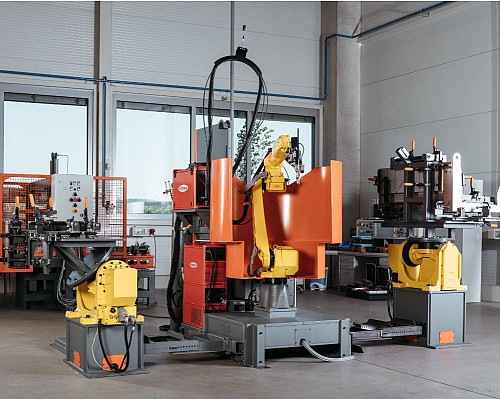

Robot welding cell for welding BA activators (2020)

The robot welding cell enables flexible welding of BA activators of different diameters. It has a robotic manipulator on a linear feed and a 2-axis positioner with a load capacity of up to 3,000 kg. It allows the table to be tilted for 90 ° from horizontal to vertical and the table rotated for 360 °. MIG/MAG welding. With the help of a laser tracking system, adaptive welding and the search for welded joints are possible.

Customer benefits:

- Excellent weld quality.

- Repeatability of welding.

- Possibility to assemble and weld several types of products.

- Increase of productivity by more than 50%.

- Reduced production costs.

- Possibility of quick change of wire of different diameters.

- Ergonomic solution for loading semi-finished products.

- The laser tracking system enables the correction of the complete welding process in real time.

Welding equipment repair service

The company employs educated and experienced staff in the field of welding equipment repair service. We respond within 24 hours and fix the problem as quickly as possible.

Cutting equipment repair service

Our employees who are in charge of servicing cutting equipment are continuously trained by our suppliers.

Consulting

Based on many years of experience, we advise you when buying equipment. We listen to our customers and dedicate all the time that is needed to find a solution together that will elevate your business to an even higher level.