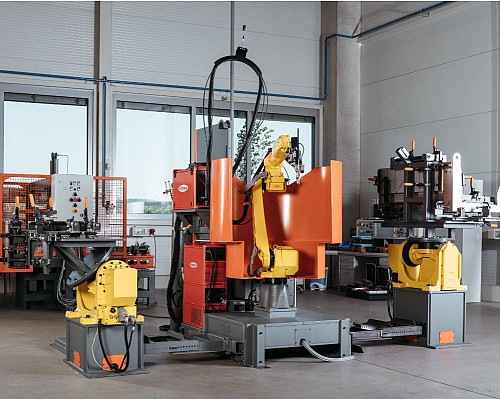

RoboFlex for welding various products (2019)

The cell consists of an ArcMate 100iC robotic manipulator on the Roboflex frame, on which a running track with a support bracket and a biaxial positioner is integrated. If the positioner mounting plate is tilted to the vertical position, welding of pieces up to a diameter of 1,000 mm and a length of 1,200 mm can be performed. In the horizontal position of the table of the biaxial positioner, it is possible to weld smaller pieces. Clamping of welds on the positioner is performed with the help of three jaw clamping heads, and for longer welding workpieces a support bracket is used. A pneumatic cylinder is mounted on the bracket, with the help of which the weld is clamped. Loading of welding workpieces is manual. Each type of welding workpiece has its own clamping tool. The opening is protected by an optical curtain. The welding process is MIG.

Customer benefits:

- Welding capacity is increased.

- Welding quality is improved.

- Reduces production costs.

- Suitable for welding various types of products.

- Also suitable for small batches.