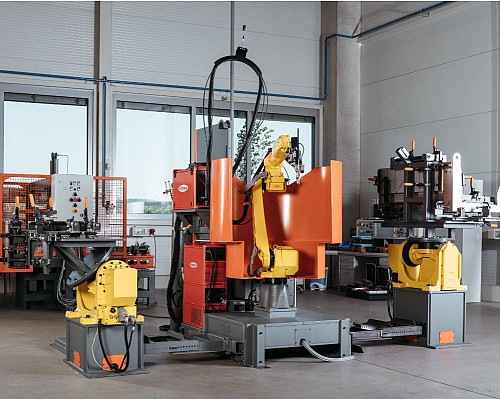

RoboFlex with quick change of welding procedures (MIG/TIG) possibility (2019)

RoboFlex cell for welding cylindrical products and hydraulic connections

The innovative and award-winning RoboFlex design meets the needs of every user. The compact RoboFlex base allows easy moving with the forklift and a very easy addition of many modules (e.g. positioners) to extend the usability of the welding robot. For welding cylindrical products and hydraulic connections, a uniaxial module with movable support is added to the RoboFlex base, which enables robotic welding of various product lengths and diameters.

Customer benefits:

- Very short training time and introduction of the robot into production.

- High productivity and welding quality.

- Reduction of welding costs.

- Possible quick change of welding procedures (MIG/TIG).

- The robotic steering control allows coordinated movements to be performed.

- Very fast and easy introduction of Offline programming with the help of the Roboguide system.

Welding equipment repair service

The company employs educated and experienced staff in the field of welding equipment repair service. We respond within 24 hours and fix the problem as quickly as possible.

Cutting equipment repair service

Our employees who are in charge of servicing cutting equipment are continuously trained by our suppliers.

Consulting

Based on many years of experience, we advise you when buying equipment. We listen to our customers and dedicate all the time that is needed to find a solution together that will elevate your business to an even higher level.