WELDCOCKPIT AI

.jpg) Stop guessing - learn about your production from facts! Take one step closer to becoming a "smart factory".

Stop guessing - learn about your production from facts! Take one step closer to becoming a "smart factory".

Keep up with the times and improve your production processes in order to optimise your output. Make the right decisions based on facts.

Keep up with the times and improve your production processes in order to optimise your output. Make the right decisions based on facts.

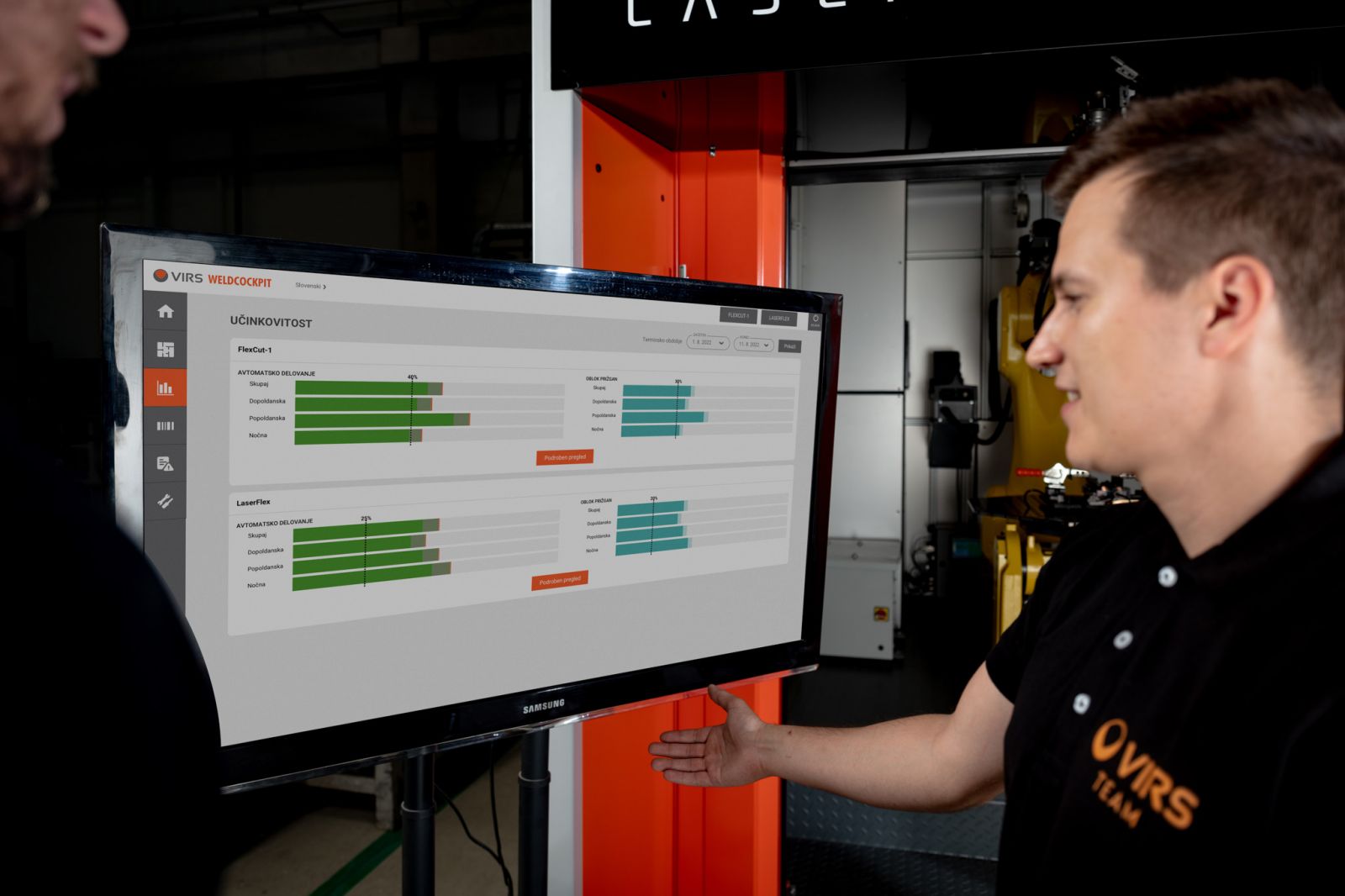

By using the WELDCOCKPIT AI software application, you will get an overview of the time, costs and efficiency of your production. It provides you with a complete overview of the production process and enables its optimisation.

Keep track of your work in real time!

The application analyses process data and graphically displays selected key indicators on the

• performance,

• utilization and

• energy efficiency of your robot cell workflow.

The software design allows you to:

- display robot activity in real time or check the history log of its operation,

- check the time and cost-effectiveness of the workflow,

- monitor the consumption of energy products and other media (wire, air, gas),

- manage the error log and document your records,

- monitoring the work of different shifts, operators, ...

- receive warnings regarding maintenance, replacement of consumables and spare parts.

Key benefits

- optimisation of time and costs in planning your production,

- availability and display of data in real time,

- data collection and printing can be tailored to your preferences,

- access to data anywhere and anytime from a PC, phone or tablet,

- provision of statistics and consequently the possibility of immediate improvement of the process,

- modern visualisation of a wide range of indicators,

- connectivity of robots from different manufacturers,

- option to choose between a basic and an extended module of processed and analysed data,

- option to send raw data to your information system,

- option to send reports (daily, weekly, monthly).

Who is the application intended for?

- Leading managers can use it to get a complete overview of productivity and economic efficiency of the production process and to quickly identify any bottlenecks.

- Production process managers can use it to monitor the technological process, energy efficiency and operation of the robotic welding process.

- Robotic cell maintenance personnel can use it to monitor the workflow and take timely action in case of any deviations.

Option to choose between a basic and an extended module. We can tailor the WeldCockpit AI application entirely to your production needs.

Option to choose between a basic and an extended module. We can tailor the WeldCockpit AI application entirely to your production needs.

"The investment is co-financed by the Republic of Slovenia and the European Union from the European Fund for Regional Development".